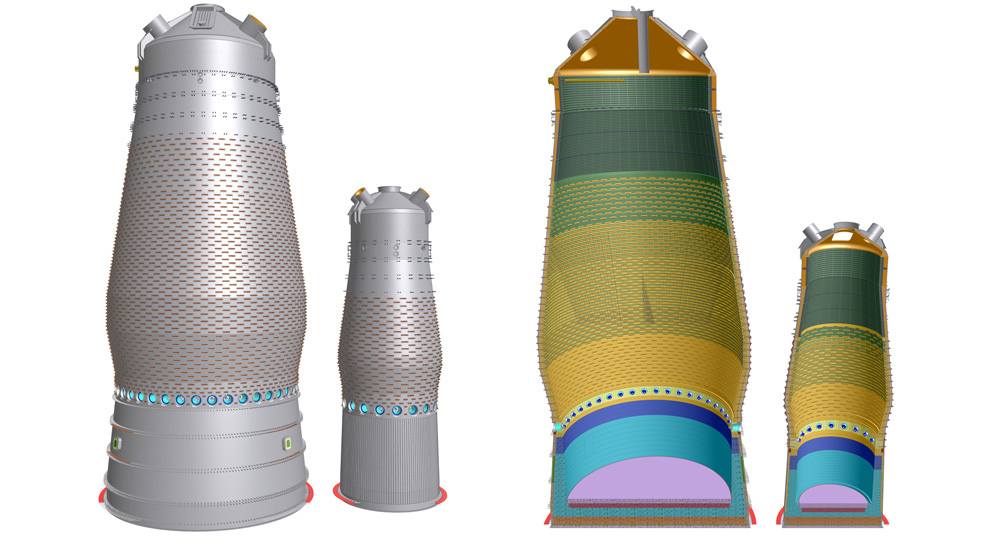

Blast Furnace

Quick and correct a proposal design

Market

The market for steel and steel products is characterized by worldwide competition and increased precision in the compostition of a great many types of steel. This requires extremely specific blast furnace formulas and furnaces that are constructed very precisely, with a high degree of risk prevention.

Assignment: Bridging the Future

Realize considerable gain of time in global proposal trajectories for formula-specific blast furnaces, improve the quality of proposal designs and reduce project risks.

Approach

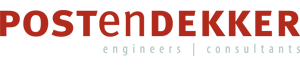

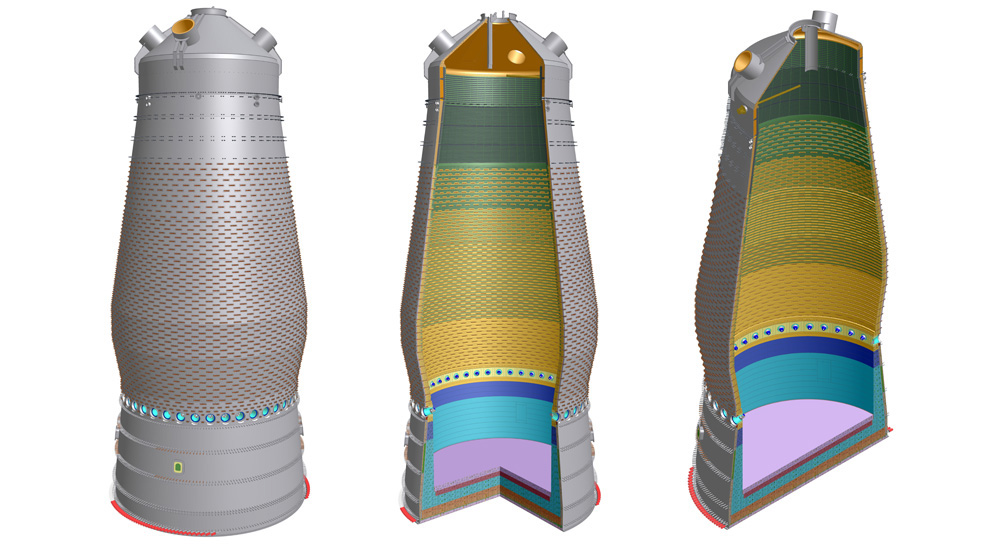

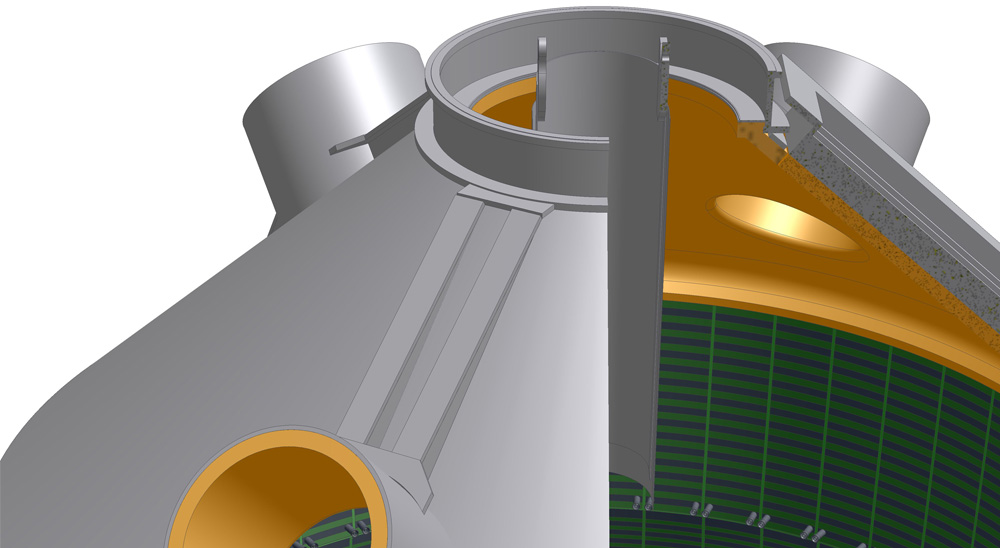

The blast furnace is for each project a client-specific design with a product structure which is a combination of assembly-to-order (ATO) and engineer-to-order (ETO) modules and parts. Post en Dekker has mapped out and secured the knowledge and configuration rules in a product configurator. The generic design of the blast furnace has been recorded in 3D CAD and is driven from the configurator. Key-users have been trained to maintain and extend the configurator. The output of the configurator consists of a proposal design and a cost estimation. This creates a supply chain that is 100% configure-to-order.

Result: Go Smart!

- The product configurator, powered by Tacton, can generate accurate proposal designs;

- 100% configure-to-order (CTO);

- Design and cost estimation within one hour;

- Increased quality of proposal design in 3D/2D CAD;

- Reduction of project risks by predictability of the design;

- Simple access and management of product and knowledge structure.

PCF is powered by TACTON.

Get in contact

Do you want more information about our programs? Or are you curious what we can do for you?

Feel free to get in contact with us.