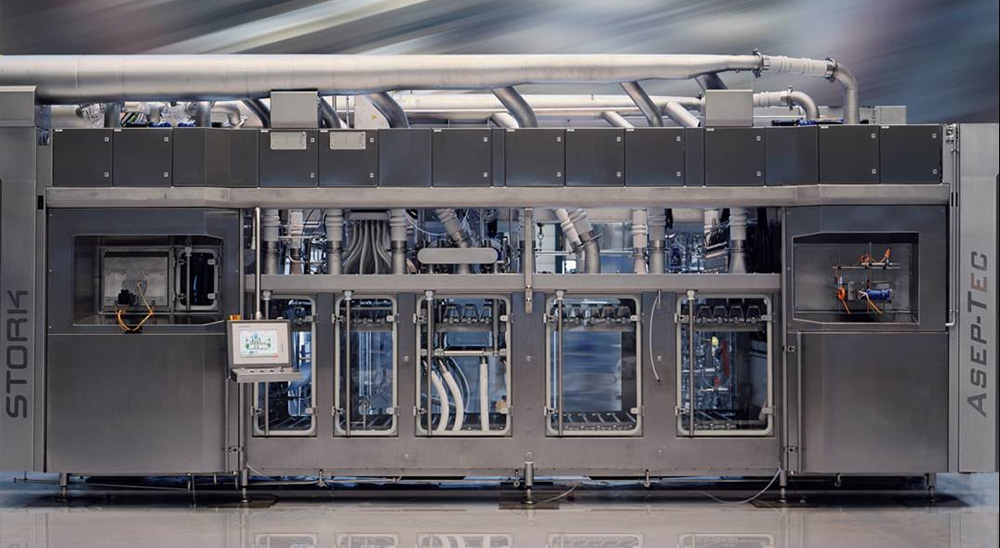

Frame Linear Filler

Cost reduction by innovation

Market

The international Food & Dairy market must, under constant pricing pressure of supermarket chains, increasingly comply with higher demands with regard to food safety. Often, problems with food hygiene make (inter)national headlines and this regularly results in high claims. The challenge is therefore to control the costs and at the same time comply with the demands of the client with a stable product family for the linear filler, which is used to fill up products in a sterile manner. This product family must be able to anticipate quickly to the many developments and of course stay within the bounderies of increasingly strict safety regulations.

The challenge for Post en Dekker was to optimize the product family for SFDS. After evaluation of the prototype wall, the basic design has been further elaborated and rolled out across four variants of the frame. Finally, the detail design has been elaborated and delivered, including 3D/2D CAD documents and SAP lists.

Assignment: Bridging the Challenge

Improving the unfavourable cost structure for the product family in order to maintain profitability under increasingly tougher pricing pressure. It is essential to shorten the lead times to the market, with in mind the ever increasing regulations and legislation.

Approach

Post en Dekker and Stork Food & Dairy Systems have mutually formulated the existing functions and issues, after which Post en Dekker took on the integral project management. In consultation with a supplier, we looked into the matter whether and how the frame for the linear filler with the help of laser welding could be produced. Part of the frame has been designed, calculated and produced as a prototype wall. Parallel to this there has been procurement.

Result: Go beat the Competition!

- Renewed design of the frame in four variants;

- Renewed supply chain, cutting-edge outsourcing;

- Reduction of delivery and assembly risks;

- Production method: laser welding; Cost reduction: 37% by optimizing the product family;

- Time-to-market: 12 weeks

Client

Stork Food & Dairy Systems, Amsterdam

Program

Get in contact

Do you want more information about our programs? Or are you curious what we can do for you?

Feel free to get in contact with us.