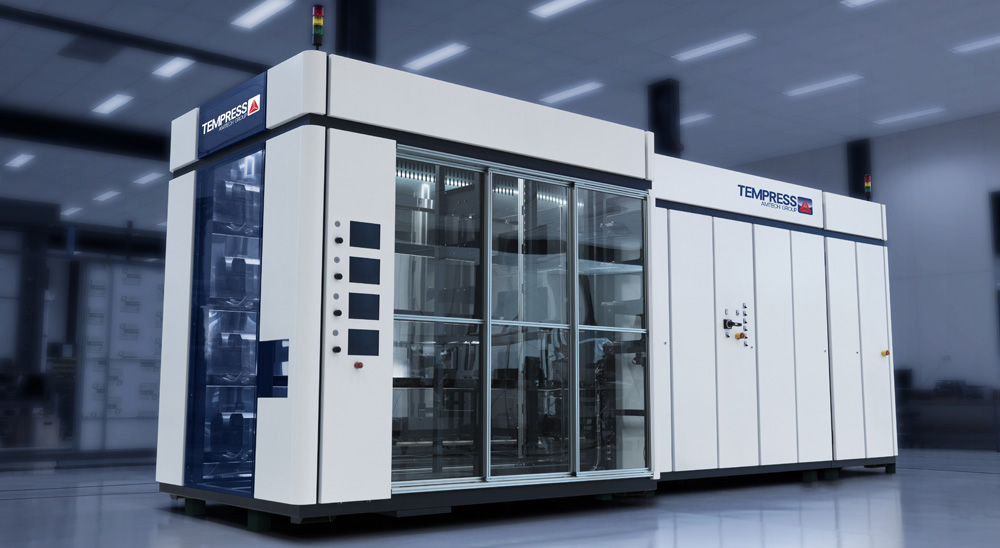

PECVD Furnace

New technology, new product family

Market

The solar industry is very dynamic and internationally competitive. Production processes change, yields increase and the market grows. Tempress saw opportunities to realize in a short period of time an overtaking manoeuvre on its competitors by extending its market position in the area of PECVD furnace systems with a four layer furnace system.

Assignment: Bridging the Challenge

Developing a completely new furnace system and preparing the series production with a strong focus on the integral cost price.

Our approach

A product family can only be successful if it complies with all demands of those involved. All users – functional, technical, logistic and commercial – have been methodically and gradually approached by Post en Dekker in close collaboration with the client. Product structuring, integral design and securing, were most important in this.

Post en Dekker developed the PECVD furnace into a modular product family with three main modules, each of which consist of dozens of permanent and optional sub modules. Important challenges in the development trajectory were the internal handling of wafers related to the machine throughput and ‘design for assembly & maintenance’. First of all, we have mapped out a complete set of specifications from client demand to machine specifications. This set of specifications was the basis of a staged project approach so we could integrally design the PECVD system. Essential here, was a strong focus on the deliverables and the staged ending according to the project method Prince2®.

Result: Go beat the competition!

Post en Dekker’s system development generated the following results:

- An innovative, modular system

- 2 test set ups for validating operation sub modules

- Successful realization and testing alfa and beta machine

- Capacity: 1600 wafers/hr

- Expected batch size: >50 machines per year

- Full implementation so that series production can be started

Get in contact

Do you want more information about our programs? Or are you curious what we can do for you?

Feel free to get in contact with us.