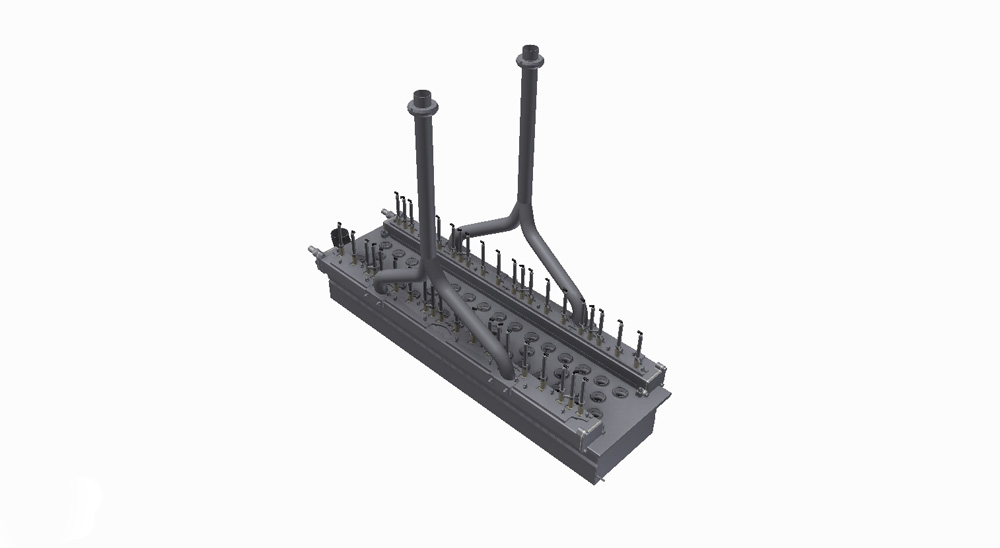

Screw Capper, Aseptic barrier module

New technology, new module

Market

Stork Food & Dairy Systems (SFDS) delivers worldwide production machines for products with with long storage life in consumer packaging. There is an increasing demand from clients for an aseptic screw capper function in the filling line, to replace the sealing with foil and then placing an external cap.

Assignment: Bridging the Gap!

Develop an aseptic screw capper function in the shape of a completely new module on the existing linear filling line. Research and process the impact of this change on connecting modules.

Approach

The Post en Dekker project team and SFDS have jointly defined the project goals. The hands-on mentality, integral approach, feeling for design, knowledge of materials and strong communicative skills, made sure there was close collaboration with foreign production companies and the technical/commercial department of SFDS.

Post en Dekker started a patent research into screw capper mechanisms and an inventory into the effects on the rest of the machine and process equipment. For the aseptic barrier that the cap should be, Post en Dekker came up with a completely new concept. This concept of course, had to fit in with the FDA standards and not infringe upon the patents for existing techniques.

Result: Go fix it!

After an intensive trajectory, Post en Dekker could realize within the planned time line:

- Extensive patents research;

- Innovative, integral product design of completely new modules for Aseptic Barrier, cap transportation and Screw Capper;

- Successful realization and testing of modules;

- Adjustments to process frames and tubes;

- Full implementation of TPD so that (series)production could be started.

Get in contact

Do you want more information about our programs? Or are you curious what we can do for you?

Feel free to get in contact with us.